Science laboratories serve as centers for exploration and discovery, where students and researchers delve into the mysteries of the natural world. Amid this pursuit of knowledge, prioritizing safety, particularly in handling potentially hazardous materials such as gases, is paramount. Gas pressure proving systems are pivotal in ensuring laboratory safety by continuously monitoring gas pressure and detecting leaks before they escalate into hazardous situations.

Understanding Gas Pressure Proving:

Gas pressure proving constitutes a proactive safety measure implemented in science laboratories to validate the integrity of gas supply systems. These systems continually monitor gas pressure to ensure it remains within safe operational limits. Upon detecting a pressure drop indicative of a leak or malfunction, the system triggers an alarm and initiates emergency shutdown protocols to avert potential hazards.

Conducting pressure drop analysis on the gas train with each activation ensures that all gas taps and appliances are securely closed and in the off position before allowing gas into the space. This test also verifies the integrity of all pipeline components, ensuring they are free from faults or damages.

Risks Associated with High and Low Gas Pressure:

High gas pressure within laboratory gas lines can lead to leaks, ruptures, and even explosions, posing significant risks to personnel and property alike. Conversely, low gas pressure can disrupt experiments, interrupt workflows, and in extreme cases, lead to asphyxiation. Numerous incidents of gas leaks and explosions in laboratories underscore the critical importance of robust safety measures such as gas pressure proving systems.

The CGS Solution:

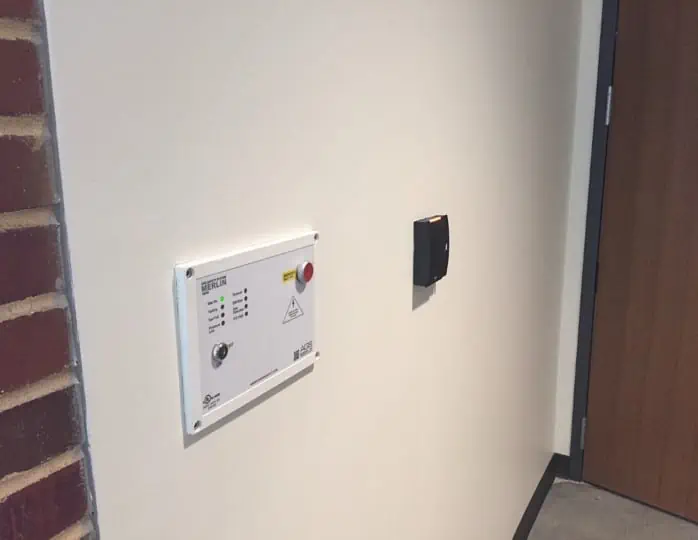

CGS offers a suite of gas pressure proving systems tailored specifically for science laboratories to enhance gas safety in these environments. This advanced system not only provides rapid emergency shutdown capabilities but also incorporates features like auto time-out and gas leak detection functionality. With integrated gas pressure proving capabilities, the Merlin 1000S range ensures continuous monitoring of gas supply systems for safe operation.

CGS solutions are already safeguarding numerous academic facilities across the United States. With over two decades of experience in manufacturing and developing a comprehensive line of high-quality gas safety systems, all UL certified and designed to meet relevant NFPA and ICC codes and standards, we stand ready to assist in designing safe and compliant projects.

Conclusion:

In science laboratories, safety remains the highest priority. Gas pressure proving systems such as the Merlin 1000S range from CGS play a pivotal role in protecting personnel, property, and ongoing experiments from the risks associated with gas leaks and pressure fluctuations. By implementing proactive safety measures and investing in advanced solutions, educators can cultivate environments that encourage exploration and innovation while ensuring the well-being of all individuals involved. Contact Canadian Gas Safety or your local representative for further information.